- To answer what a DPF is, I think it is important to know how the DPF works in sync with the 2 other NOX reduction systems.

*2003-2006 engines (not to be confused with the year of the truck itself)

E.G.R. (Exhaust Gas Recirculation) This technology was the first part of the equation and met NOX standards starting with 2003 to 2006 year model engines. This reduction technique re-circulates a portion of the engine’s exhaust gas back into the cylinders a second time. NOX gas is created by mixing nitrogen and oxygen with extreme temperatures under pressure. The EGR creates a cooler temperature in the lower combustion chambers eliminating some of the NOX gas in the engine. Not great for the performance of the engine but did do the trick to meet the 2003 NOx emission standard.

*2007-2009 engines

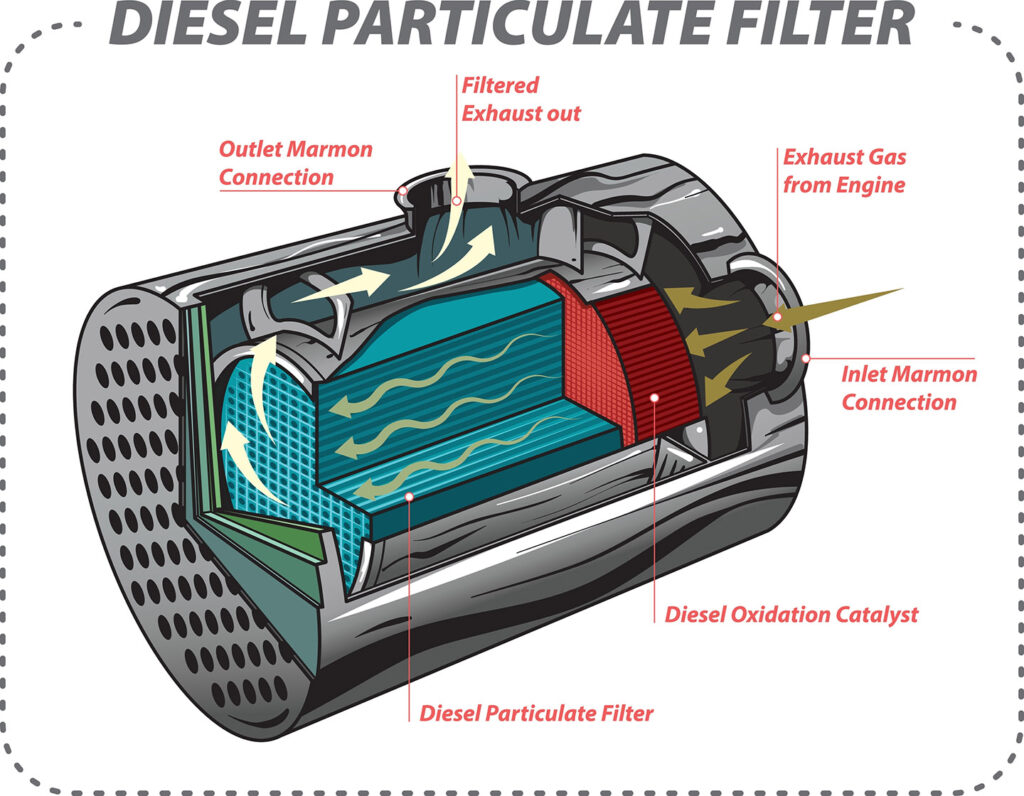

D.P.F. (Diesel Particulate Filter) This filter was introduced to the engines in tandem with the EGR System in 2007. This filter takes on what the EGR does not catch coming out of the engine due to incomplete combustion of fuel (black Carbon) and traps much of those particulates directly on the filters surface. I have found that there are many types of DPF designs but all must meet similar requirements.

A common filter is made of Cordierite (a ceramic material in a honeycomb design). The Air flow is forced into the filter trapping the majority of the particulates. This is not a single use filter once full of soot. This DPF can turn the soot to ash in 2 ways before the filter is needed to be emptied out or “cleaned”. To do that the DPF requires a Catalyst called the D.O.C (Diesel Oxidation Catalyst) where the exhaust passes over the DOC before it goes into the filter. This is called a passive regeneration that happens when the truck is running down the road at operational temperature. The second way to take the filters accumulated soot and turn it to ash is by using extra fuel ignited from an injector to increase the temperature of the DOC. Soot brakes down into ash only at high temperatures. By burning fuel over the DOC elevating to extreme temperature into the filter soot is changed to ash and stored in the filter. Once that filter is full of ash the filter is pulled out inspected and cleaned of all ash ready to be reinstalled on the truck.

Engine Manufacturers suggested cleaning: In the real world 350,000 miles is ambiguous at best. In years past we have had all engine Manufacturer’s at our convention on a panel saying there is really no way to know when to clean a DPF. However the industry is finding that as each time the filter is cleaned the interval will decreases until it finally does need to be replaced.

Contamination or cracking of a DPF: The DPF rarely fails on its own. It usually will fail due to something malfunctioning “upstream”. The DOC plugging, EGR leaking coolant into the filter and oil from a blown turbo to name a few will cause the DPF to fail.

*2010 and newer engines

D.E.F. (Diesel Exhaust Fluid): this was the last technology that brought the industry across the C.A.R.B.s finish line. I will not get into too much detail with this system. In short, the DEF is sprayed into the exhaust system changing the majority of the NOx particulates into inert ammonia.

One common misnomer many in the industry still have is that a DEF engine does not have a DPF filter. Without all (3) systems working together engine manufacturers could not have brought NOx emissions down to C.A.R.B. mandated levels. Many of my customers say they should be paid for cleaning the air as what air goes into the engine is coming out arguably cleaner.

If you own a diesel vehicle, you should be familiar with what’s known as the diesel particulate filter, or DPF. Every diesel engine has one to prevent soot and ash from leaking into the exhaust. These particulates reduce air quality and are considered hazardous to those with respiratory conditions. If you’re new to this technology, learn how a diesel particulate filter works, when to change it and how to clean it.

What Does a Diesel Particulate Filter Do?

Diesel exhaust systems can generate all kinds of particulates, including soot, ash and other forms of debris. The DPF is designed to filter out these substances, so the engine runs clean.

It is usually made of a ceramic substrate in the shape of a honeycomb, which helps it collect debris. It is located ahead of the NOx trap and the exhaust pipe but after the temperature sensor.

If you look inside the filter, you will see around 200 cells per square inch, with each cell measuring 3/64″ square. Before the exhaust moves through the filter, the air must first be oxidized by a catalyst. The inlet cells on the DPF are plugged at the opposite end, which forces the air through the filter. The particulates become trapped in the substrate walls, which allows the clean air to move past the filter.

When to Change Your Diesel Particulate Filter Call 0468377999

Experts agree that it’s best to clean your diesel particulate filter every 100,000 to 150,000 klms, but this is just a rough estimate. It all depends on how you drive. If you spend most of your time at low speeds, the filter will likely get clogged sooner rather than later.

Failing to clean the DPF will cause it to fail, which means you could end up replacing it every 1500,000 klms or so. If you keep the filter clean, you shouldn’t have to replace it as often. It’s all a part of your annual maintenance checklist. However, once you pass the 100,000 klms threshold, it’s only a matter of time before the device fails outright. At that point, you may need to find replacement diesel particulate filters.

Other factors can cause the DPF to fail sooner than expected. If the fuel isn’t kept at the right pressure, the filter will clog prematurely. Consider finding replacement IPR valves if your filter is failing more often than normal.

How to Clean Your Diesel Particulate Filter Call 0468377999

With all that soot and debris running through your filter, it will get dirty from time to time. There are several ways to clean a DPF.

Most exhaust systems will automatically clean the filter using excess heat. This is what’s known as passive regeneration. The added heat burns away the soot and debris, turning the carbon into carbon monoxide. This allows the gas to pass through the filter. Passive regeneration happens nearly every day, usually at high speeds, even if you don’t realize it.

If the engine isn’t producing enough heat to get rid of the debris, it will need to use what’s known as active regeneration. The engine will inject fuel into the exhaust system. It will then be oxidized to generate heat, which converts the soot into carbon monoxide.

You can also add DPF cleaner to the fuel to help the engine get rid of excess soot using regeneration. The cleaner mixes with the particles to create a new compound that can be burned at lower temperatures.

However, this won’t work on ash. No amount of heat can convert ash into CO, so you’ll need to physically remove the filter and clean it by hand. Afterward, you can reinstall it and use it for another 150,000 klms or so, depending on operating conditions.

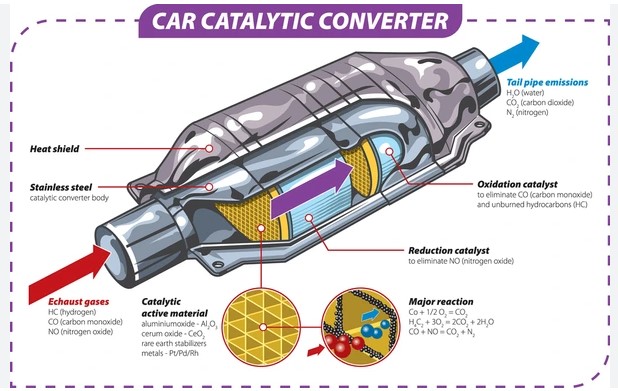

CATALYTIC CONVERTER

YOUR SOLUTION 0468377999

OUR 10 STAGE CLEANING PROCESS

PROCESS CALL 0468377999

WE KEEP YOU INFORMED DAILY

-

- 1 – Tag / engrave part with Rego / VIN / our Job ID code

- 2 – Examine

- 3 – Photograph

- 4 – Pressure clean

- 5 – At our option – Chemical treatment – organic- acid -alkali depending on part

- 6 – Pressure clean

- 7 – Ultrasonic cleaning 1-6 cycles as required then pressure rinse / wash

- 8 – Photograph

- 9 – Clean and dry / Wrap* subject to requirements

- 10 -[Premium service only – Air flow test Report]

- 11 – Guarantee to owner T&C apply

- READY TO COLLECT OR DELIVER